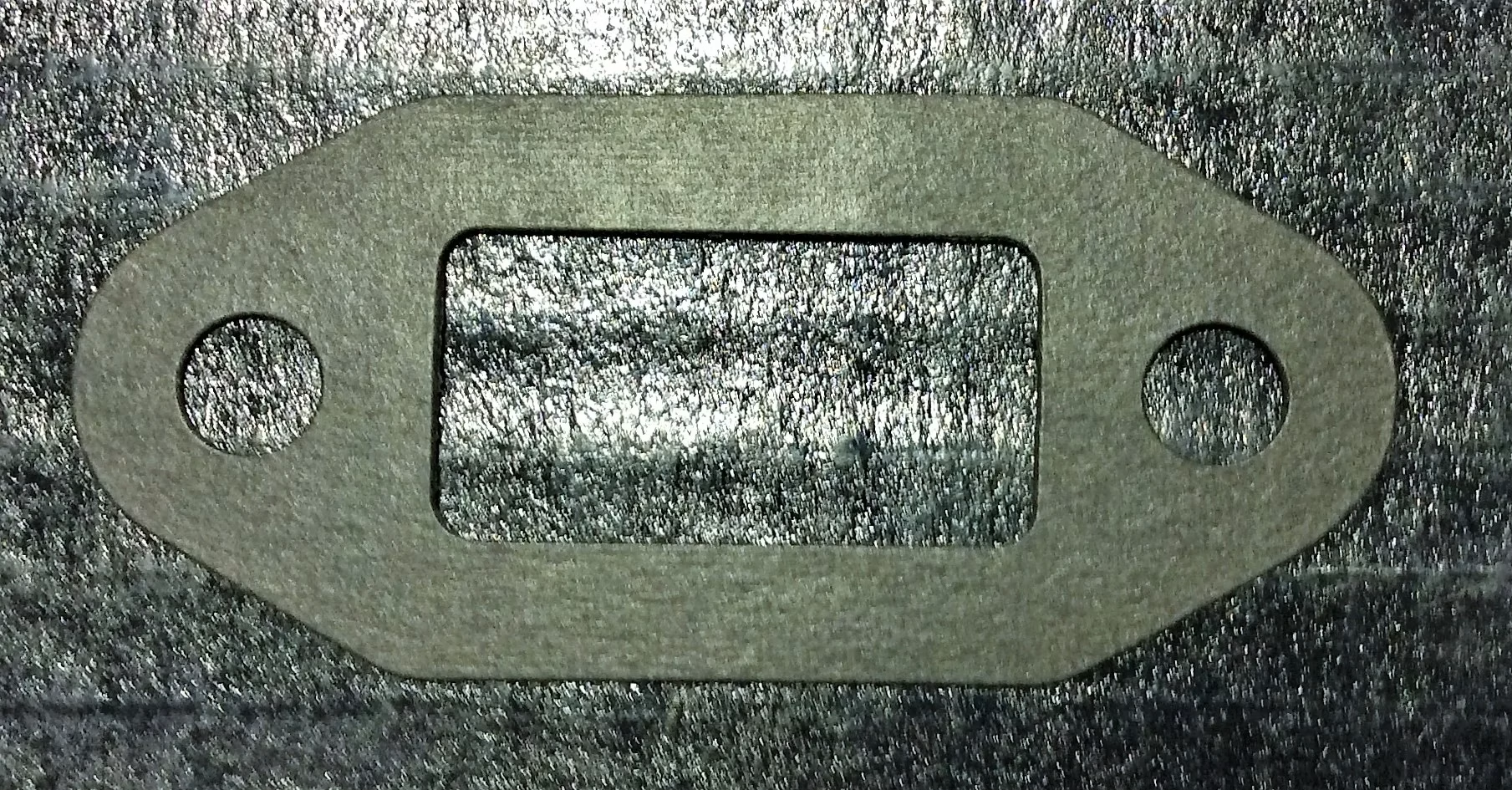

GS21101 Steel (OE Style) Valley Pan Intake Gasket

March 20, 2018

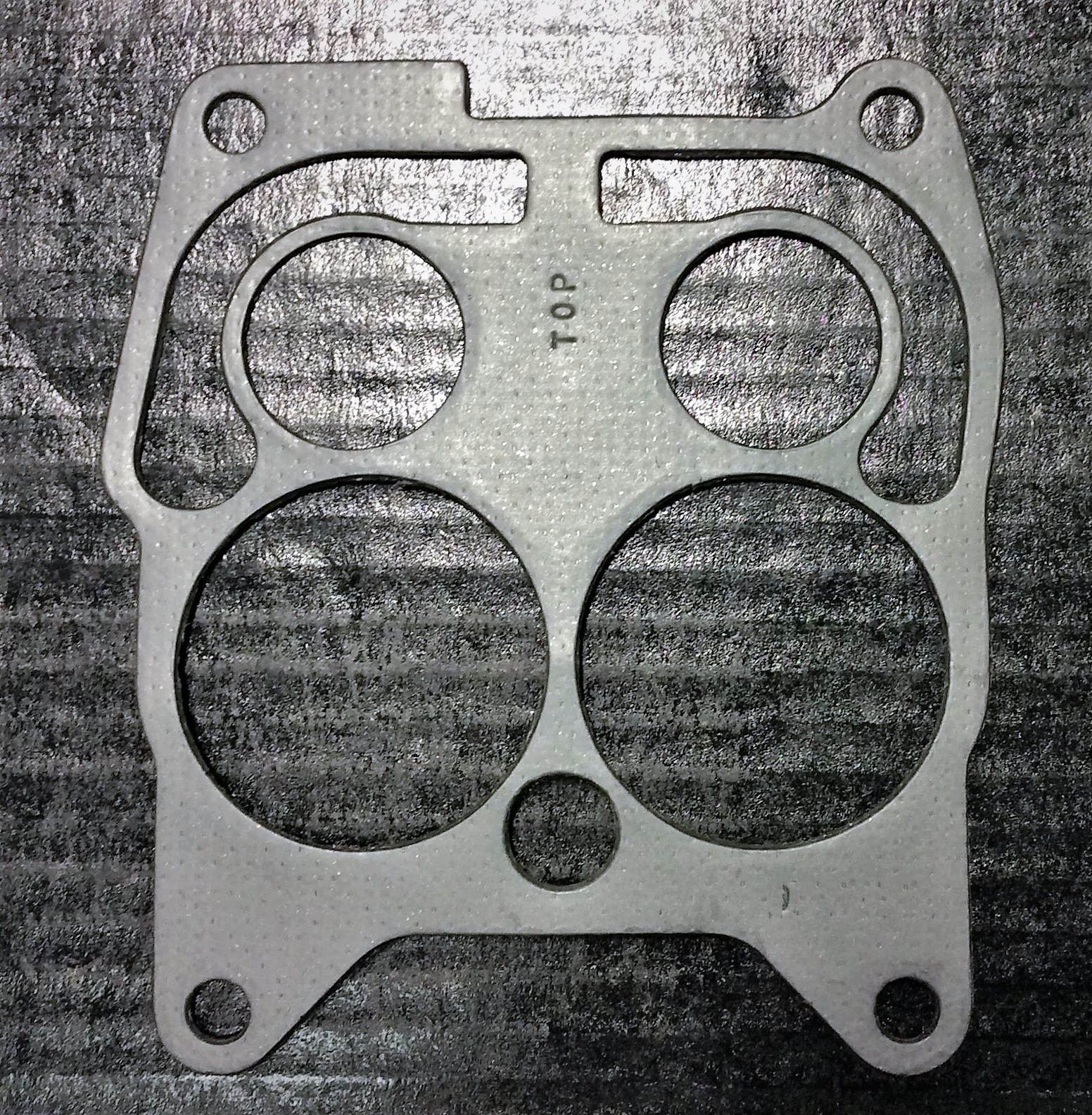

GS10211 Carb Gasket ’67-’70

March 20, 2018GS21112 Cad Company Composite Intake Gaskets

$28.00

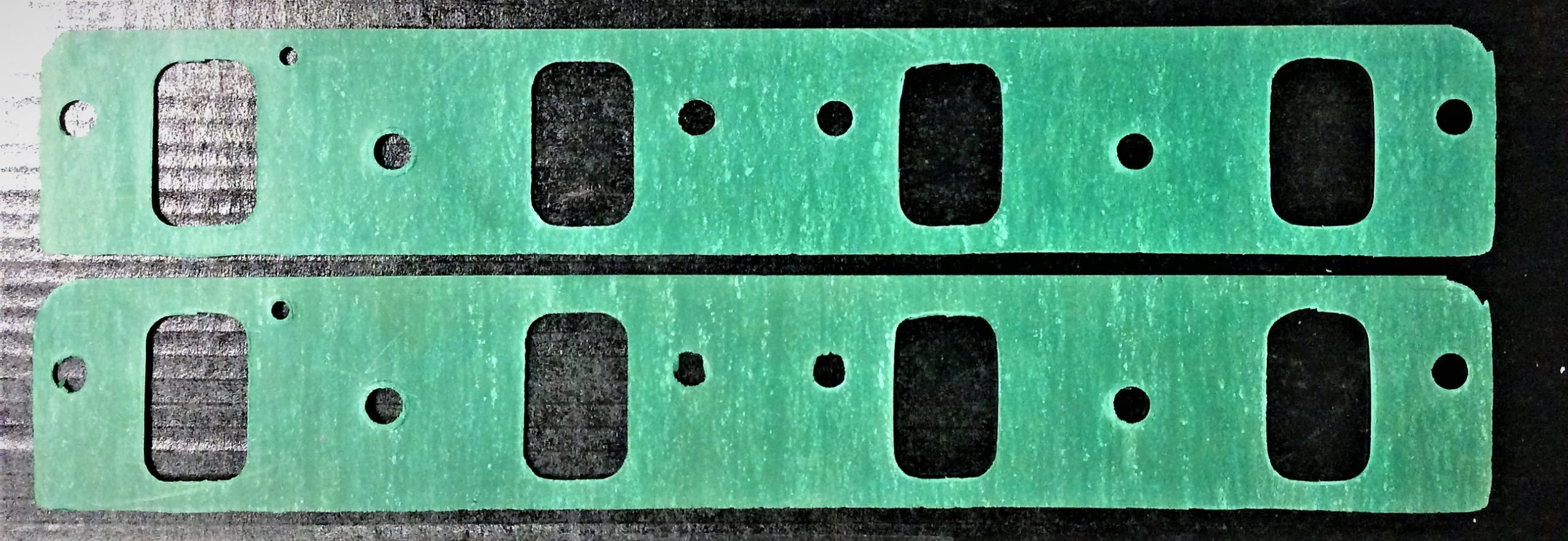

Cad Company Composite Intake Gaskets

For use with heads with the standard intake port configuration (factory heads, ported or not, and most non-BoogieMan aluminum heads).

Blocks exhaust crossover through intake (can be trimmed to allow crossover flow if needed).

Won’t burn through at crossover or come apart when wet.

High quality composite gasket material. Safe (and recommended for) for aluminum heads and intakes.

Color may vary.

Made in USA

Cad Company Composite Intake Gaskets

For use with heads with the standard intake port configuration (factory heads, ported or not, and most non-BoogieMan aluminum heads).

Blocks exhaust crossover through intake (can be trimmed to allow crossover flow if needed).

Won’t burn through at crossover or come apart when wet.

High quality composite gasket material. Safe (and recommended for) for aluminum heads and intakes.

Color may vary.

For wide-port (BoogieMan) applications, we recommend the BoogieMan intake gaskets (if the intake or head (or both), has the BoogieMan port configuration).

For BoogieMan™ applications, please order GS21122.

We do not offer raised port intake gaskets.

Made in USA

These gaskets are intended to be installed dry (no sealer needed on the gaskets). You may use a light mist of gasket adhesive, to help hold them in place if needed, but anything else is far more likely to cause a leak, than to prevent one. We recommend a bead of silicone to seal the intake to the block, across the front and back of the engine. Be sure to get silicone under the corner of the head at each end of these seals.

These gaskets block the exhaust crossover by default, which is worth a little power, but can be opened up for applications needing a functional exhaust crossover (such as for EGR or divorced choke functionality on a stock intake, or cold weather driving with a stock, Edelbrock, or PC3 intake). They are made of a fire-resistant material so they won’t burn through under normal conditions (they will still fail in some conditions, such as if one side of your exhaust is locked for some reason).

If you are using stock exhaust manifolds, you will need to disable (by disconnecting the vacuum hose on later engines) or better yet, wire open or remove the EFE valve. This is a flapper valve mounted to the end of most passenger side exhaust manifolds, that is intended to be closed when the engine is cold, to force most of the exhaust to go through the intake crossover for improve warm-up in cold weather. If this closes, or you get an obstruction in one side of your exhaust system, damage to the composite intake gaskets is likely (unless you’ve opened up the gasket to allow the crossover to work).

If you look at your head and intake, you will see what looks like a 5th intake port, right in the middle (front to rear). This is not present on aluminum heads and some aftermarket intakes. The port in the head connected to an exhaust port, and the port in the intake connects to the matching port on the other side, which allows exhaust to flow under the plenum to warm it up quickly in cold weather. This costs you 10 HP or more (based on dyno testing) once the engine is warmed up, depending on your engine combination. The crossover also provides the heat to open the choke on stock ’73-older engines with a divorced choke, as well as feeding the EGR valve on stock mid-70 and newer intakes.

Opening up the crossover: The easiest way to open up these gaskets to allow the exhaust crossover to function as intended, is with a hammer. Warning: these gaskets are very difficult to cut with normal cutting implements, and trying to do so may result in injury. However, a ball-peen hammer (or any hammer in a pinch) can be used to cut the hole quite easily. Simply lay the gasket in place on the head, with the bolt holes lined up. For some folks, securing it with masking tape helps, but if you use tape that’s too sticky, you may damage the gasket removing the tape. Then, tap (not beat) on the gasket, around the edge of where the port opening in the head is. Where the cast opening meets the machined gaskets surface, there is a very sharp edge, which will cut through the gasket in the exact shape of the port opening as you tap around it.

We recommend aftermarket intake gaskets for _all_ applications using an aluminum intake or heads, as the mild steel factory gasket does not always play nice with the aluminum, when exposed to moisture (including humidity), and can result in bi-metallic corrosion that will eventually cause a vacuum leak. In the desert, our testing has shown that it takes more than 10 years for that to become a problem, but in the mid-west, it can often be less than half a year. Reports from customers on the coasts indicate that environment may cause failure in less than a month in certain conditions.

| Weight | 16 oz |

|---|---|

| Dimensions | 4 × 4 × 24 in |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.